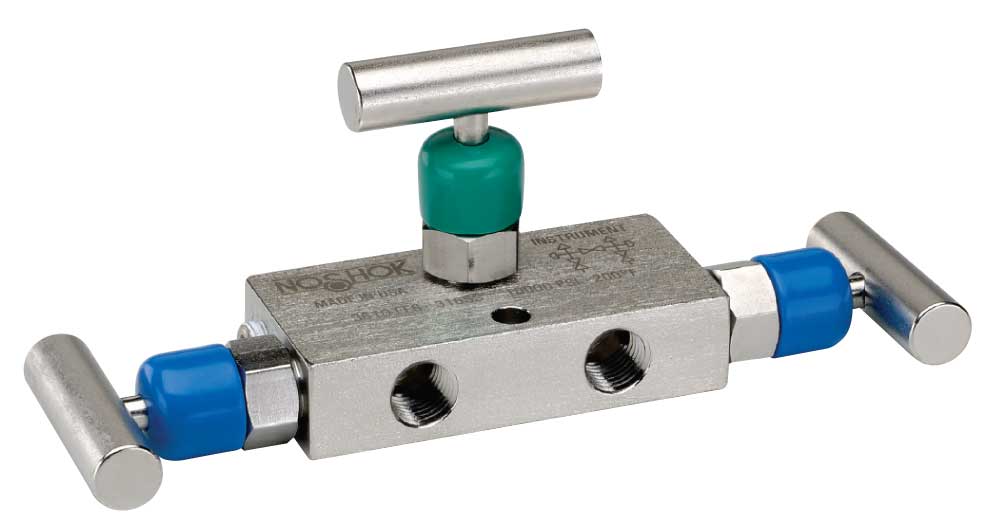

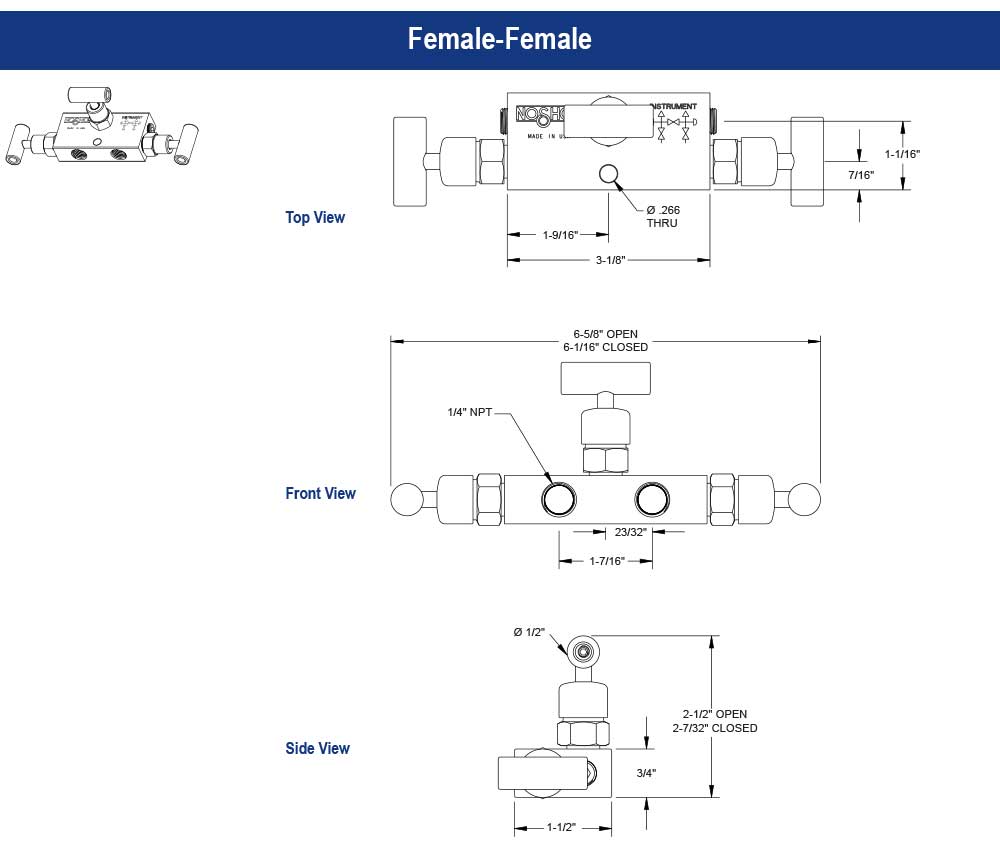

Noshok 3610-FFS 3-Valve Differential Pressure Mini Manifold Valve HARD SEAT 1/4 NPT Female x 1/4 NPT Female, 316 SS

$397.50 Original price was: $397.50.$255.60Current price is: $255.60.

115 in stock

Noshok 3610-FFS 3-Valve Differential Pressure Mini Manifold Valve HARD SEAT 1/4 NPT Female x 1/4 NPT Female, 316 SS

3610/3710 Series 3-Valve Differential Pressure Mini Manifold Valves

Hard Seat & Soft Tip (0.141″ Orifice)

- Compact design is ideal for installations with limited space, such as

behind panels or in cabinets - Designed for use with differential pressure transmitters incorporating

two isolation valves and an equalizing valve in differential pressure

measurement - 100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance

and reliability - Soft tip valves feature a patented Delrin® non-rotating soft tip stem, and a

back-up metal-to-metal seal (U.S. Patent 6,820,857) - 3610 Series hard seat valves have 10,000 psi pressure rating @ 200 °F

- 3710 Series soft tip valves have 6,000 psi pressure rating @ 200 °F

- Blow-out proof stem provides a secondary stem seal in the full

open position - FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Grafoil® packing optional

- All stems are 316 stainless steel

- All stem threads are rolled for strength and ease of operation

- One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

- Vinyl dust caps for bonnets and stems (non-packing)

- Patented body-to-bonnet, metal-to-metal seal is designed to significantly

increase the pressure range of the valve (U.S. Patent 7,758,014)

ORDERING INFORMATION

| SERIES | 3 | 3-valve | ||||

| SEATS | 6 | Hard seat | 7 | Soft tip | ||

| PROCESS TYPE | 1 | Differential pressure | ||||

| CONNECTION | 0 | 1/4″ NPT | ||||

| VALVE TYPES | FFC | Female-Female, Steel | FFS | Female-Female, Stainless Steel |

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

To meet all of your specific application requirements, the following additional options are available for these manifold valves. To order all or any of these options, simply add them to the part number as shown in the diagram below.

NOTE 1: The example shown includes ALL possible additional options. Please include ONLY the options required for your application when building your part number. (EXAMPLE: 3610-FFC-P1)

NOTE 2: When a packing option is selected, an o-ring option is NOT available.

NOTE 3: The standard o-ring in all the NOSHOK manifold valves is FKM.

ORDERING INFORMATION – Additional Options

| PACKINGS† | P1 | PTFE | P2 | Grafoil® | ||||

| STEM TIPS | T1 | Non-rotating (316 stainless)** | T4 | PEEK*** | T7 | Ball (ceramic)** | T10 | Regulating Delrin®*** |

| T2 | Delrin® (Acetal)*** | T5 | Ball (440C stainless)** | T8 | Ball (Monel)** | T11 | Regulating PCTFE*** | |

| T3 | PCTFE*** | T6 | Ball (carbide)** | T9 | Regulating hard** | T12 | Regulating PEEK*** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Kalrez® 3018 or equivalent) | NB1 | NBR | ||

| HANDLES | HL2 | 2-1/2″ “T” | HL4 | 1-3/8″ Phenolic | ||||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For 3610 only.

*** For 3710 only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are 1-3/8″ mini “T” handles (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, the 1-3/8″ mini “T” handle (HL7) on the 3710-FFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.

Description

Noshok 3610-FFS 3-Valve Differential Pressure Mini Manifold Valve HARD SEAT 1/4 NPT Female x 1/4 NPT Female, 316 SS

3610/3710 Series 3-Valve Differential Pressure Mini Manifold Valves

Hard Seat & Soft Tip (0.141″ Orifice)

- Compact design is ideal for installations with limited space, such as

behind panels or in cabinets - Designed for use with differential pressure transmitters incorporating

two isolation valves and an equalizing valve in differential pressure

measurement - 100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance

and reliability - Soft tip valves feature a patented Delrin® non-rotating soft tip stem, and a

back-up metal-to-metal seal (U.S. Patent 6,820,857) - 3610 Series hard seat valves have 10,000 psi pressure rating @ 200 °F

- 3710 Series soft tip valves have 6,000 psi pressure rating @ 200 °F

- Blow-out proof stem provides a secondary stem seal in the full

open position - FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Grafoil® packing optional

- All stems are 316 stainless steel

- All stem threads are rolled for strength and ease of operation

- One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

- Vinyl dust caps for bonnets and stems (non-packing)

- Patented body-to-bonnet, metal-to-metal seal is designed to significantly

increase the pressure range of the valve (U.S. Patent 7,758,014)

ORDERING INFORMATION

| SERIES | 3 | 3-valve | ||||

| SEATS | 6 | Hard seat | 7 | Soft tip | ||

| PROCESS TYPE | 1 | Differential pressure | ||||

| CONNECTION | 0 | 1/4″ NPT | ||||

| VALVE TYPES | FFC | Female-Female, Steel | FFS | Female-Female, Stainless Steel |

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

To meet all of your specific application requirements, the following additional options are available for these manifold valves. To order all or any of these options, simply add them to the part number as shown in the diagram below.

NOTE 1: The example shown includes ALL possible additional options. Please include ONLY the options required for your application when building your part number. (EXAMPLE: 3610-FFC-P1)

NOTE 2: When a packing option is selected, an o-ring option is NOT available.

NOTE 3: The standard o-ring in all the NOSHOK manifold valves is FKM.

ORDERING INFORMATION – Additional Options

| PACKINGS† | P1 | PTFE | P2 | Grafoil® | ||||

| STEM TIPS | T1 | Non-rotating (316 stainless)** | T4 | PEEK*** | T7 | Ball (ceramic)** | T10 | Regulating Delrin®*** |

| T2 | Delrin® (Acetal)*** | T5 | Ball (440C stainless)** | T8 | Ball (Monel)** | T11 | Regulating PCTFE*** | |

| T3 | PCTFE*** | T6 | Ball (carbide)** | T9 | Regulating hard** | T12 | Regulating PEEK*** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Kalrez® 3018 or equivalent) | NB1 | NBR | ||

| HANDLES | HL2 | 2-1/2″ “T” | HL4 | 1-3/8″ Phenolic | ||||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

Please consult your local NOSHOK Distributor or NOSHOK, Inc. for availability and delivery information.

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For 3610 only.

*** For 3710 only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are 1-3/8″ mini “T” handles (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, the 1-3/8″ mini “T” handle (HL7) on the 3710-FFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.