NOSHOK 210002-MMS-P1-T1 2 Valve Manifold, Soft Seat, Flange x Flange w/ 1/4 NPT Vent, 316 SS, PTFE Packing, Non-Rotating Tip

$432.22 Original price was: $432.22.$299.99Current price is: $299.99.

NOSHOK 210002-MMS-P1-T1 2 Valve Manifold, Soft Seat, Flange x Flange w/ 1/4 NPT Vent, 316 SS, PTFE Packing, Non-Rotating Tip

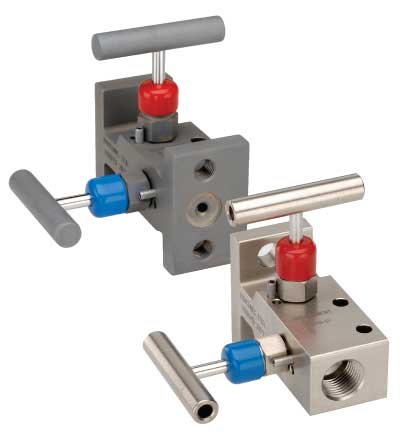

200002/210002 & 200402/210402 Series 2-Valve Narrow Block & Bleed Manifold Valves Hard Seat & Soft Seat

- Combines isolating and venting in a single valve, eliminating the need for tubing and fittings

- Block valve isolates the downstream process fluids and the bleed valve exhausts upstream fluids enabling static pressure transmitters, switches or gauges to be removed without disturbing the permanent piping installation

- Block valve is located on the left side and the bleed valve is located on top in a 90° orientation, venting is to the right

- 100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

- 200002/200402 Series hard seat valves have 10,000 psi pressure rating @ 200 ºF

- 210002/210402 Series soft seat valves have 6,000 psi pressure rating @ 200 ºF

- 210002/210402 Series valves also feature a replaceable Delrin® seat, and straight through porting for bidirectional, high capacity flow and easy roddable cleaning

- PCTFE or PEEK soft seat optional

- Blow-out proof stem provides a secondary stem seal in the full open position

- FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

- All stems are 316 Stainless Steel

- Stem and bonnet threads are rolled for strength and ease of operation

- One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

- Slotted spring pin to prevent accidental loosening

- Vinyl dust caps for bonnets and stems (non-packing)

200002/210002 & 200402/210402 Series 2-Valve Narrow Block & Bleed Manifold Valves Hard Seat & Soft Seat

If you are viewing on a smaller screen or with screen zoom, please use the horizontal scroll bar at the bottom of this table to see all information.

ORDERING INFORMATION

| SERIES | 2 | 2-valve | ||||

| SEATS | 0 | Hard seat | 1 | Soft seat | ||

| PROCESS TYPE | 0 | Static pressure | ||||

| CONNECTIONS | 0 | Flange-flange | 2 | 1/4″ NPT-flange | 4 | 1/2″ NPT-flange (standard) |

| VALVE TYPES | MFC | Flange-Female, Steel | MMS | Flange-Flange, Stainless Steel | MMCL | Flange-Flange, Steel, Left Vent |

| MFS | Flange-Female, Stainless Steel | MFCL | Flange-Female, Steel, Left Vent | MMSL | Flange-Flange, Stainless Steel, Left Vent | |

| MMC | Flange-Flange, Steel | MFSL | Flange – Female, Stainless Steel, Left Vent |

ORDERING INFORMATION – Additional Options

| PACKINGS† | P1 | PTFE | P2 | Graphite ** | ||

| STEM TIPS | T1 | Non-rotating (316 stainless) | T6 | Ball (carbide)** | T8 | Ball (Monel)** |

| T5 | Ball (440C stainless) ** | T7 | Ball (ceramic)** | T9 | Non-rotating regulating (316 Stainless)** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Kalrez® 3018 or equivalent) | NB1 | NBR |

| HANDLES | HL1 | 1-13/16″ Mini “T” | HL4 | 1-3/8″ Phenolic | ||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For hard seat only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are block “T” handles (HL2) and bleed 1-3/8″ mini “T” handle (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, the “T” handle (HL2) on the 200402-MFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.

Description

NOSHOK 210002-MMS-P1-T1 2 Valve Manifold, Soft Seat, Flange x Flange w/ 1/4 NPT Vent, 316 SS, PTFE Packing, Non-Rotating Tip

200002/210002 & 200402/210402 Series 2-Valve Narrow Block & Bleed Manifold Valves Hard Seat & Soft Seat

- Combines isolating and venting in a single valve, eliminating the need for tubing and fittings

- Block valve isolates the downstream process fluids and the bleed valve exhausts upstream fluids enabling static pressure transmitters, switches or gauges to be removed without disturbing the permanent piping installation

- Block valve is located on the left side and the bleed valve is located on top in a 90° orientation, venting is to the right

- 100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

- 200002/200402 Series hard seat valves have 10,000 psi pressure rating @ 200 ºF

- 210002/210402 Series soft seat valves have 6,000 psi pressure rating @ 200 ºF

- 210002/210402 Series valves also feature a replaceable Delrin® seat, and straight through porting for bidirectional, high capacity flow and easy roddable cleaning

- PCTFE or PEEK soft seat optional

- Blow-out proof stem provides a secondary stem seal in the full open position

- FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

- All stems are 316 Stainless Steel

- Stem and bonnet threads are rolled for strength and ease of operation

- One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

- Slotted spring pin to prevent accidental loosening

- Vinyl dust caps for bonnets and stems (non-packing)

200002/210002 & 200402/210402 Series 2-Valve Narrow Block & Bleed Manifold Valves Hard Seat & Soft Seat

If you are viewing on a smaller screen or with screen zoom, please use the horizontal scroll bar at the bottom of this table to see all information.

ORDERING INFORMATION

| SERIES | 2 | 2-valve | ||||

| SEATS | 0 | Hard seat | 1 | Soft seat | ||

| PROCESS TYPE | 0 | Static pressure | ||||

| CONNECTIONS | 0 | Flange-flange | 2 | 1/4″ NPT-flange | 4 | 1/2″ NPT-flange (standard) |

| VALVE TYPES | MFC | Flange-Female, Steel | MMS | Flange-Flange, Stainless Steel | MMCL | Flange-Flange, Steel, Left Vent |

| MFS | Flange-Female, Stainless Steel | MFCL | Flange-Female, Steel, Left Vent | MMSL | Flange-Flange, Stainless Steel, Left Vent | |

| MMC | Flange-Flange, Steel | MFSL | Flange – Female, Stainless Steel, Left Vent |

ORDERING INFORMATION – Additional Options

| PACKINGS† | P1 | PTFE | P2 | Graphite ** | ||

| STEM TIPS | T1 | Non-rotating (316 stainless) | T6 | Ball (carbide)** | T8 | Ball (Monel)** |

| T5 | Ball (440C stainless) ** | T7 | Ball (ceramic)** | T9 | Non-rotating regulating (316 Stainless)** | |

| O-RINGS* | EM1 | EPDM | KZ1 | FFKM (Kalrez® 3018 or equivalent) | NB1 | NBR |

| HANDLES | HL1 | 1-13/16″ Mini “T” | HL4 | 1-3/8″ Phenolic | ||

| HL3 | 1″ Round knurled | HL5 | 1-3/4″ Phenolic |

† If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the “Pressure vs Temperature: Packing Style with Compatible Fluid” chart.

* Other o-ring materials available on request.

** For hard seat only.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are block “T” handles (HL2) and bleed 1-3/8″ mini “T” handle (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, the “T” handle (HL2) on the 200402-MFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.